Solenoid Valves for Coffee Machines

M&M International solenoid valves have been a popular brand for coffee machine manufacturers for over 40 years. The high quality and reliability/price ration make certain models ideal for use in the quality brand machines. The M&M valves have been used in many types of coffee machine, from domestic and industrial machines to dispensing machines. In this blog, we look at Solenoid Valves for Coffee Machines and how they operate.

Cartridge Coffee Dispensers

Semi-automatic coffee-in-cartridge dispensers complete with hot water delivery heads are to supply coffee and soluble beverages in a cartridge. The hydraulically moved coffee infusion unit automatically expels the cartridge into the specially provided container. We can equip the dispenser with a support cabinet with cup dispenser, spoon and sugar drawer and product storage compartment with a door. Small dimensions and easiness of use make them widely suitable for household appliances but also in shops, offices, associations, laboratories, hotels and wherever there is no need for a constant supply.

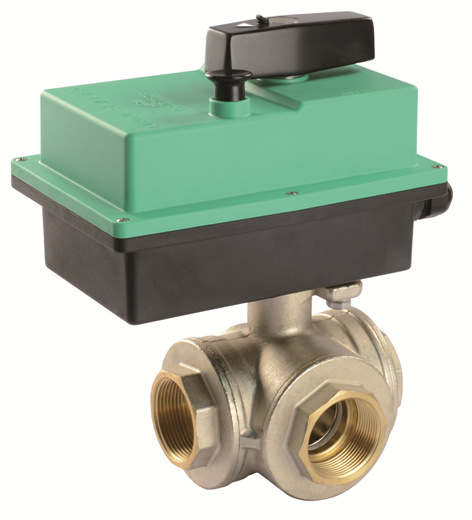

Two three-way solenoid valves intercept the water that the vibrating pump sucks up from the tank which contains the water. The former supplies the hydraulic actuator, the latter delivers water to the boiler. An external thermostat can adjust the hot water temperature inside the hot water. We can instal it on the actuator stem and equip it with a nozzle that delivers hot water when you press it.

The Operation

The operation starts when the cartridge is in; the two solenoid valves open at the same time and the actuator pushes the boiler downwards against the cartridge. A safety valve above the second solenoid valve prevents water from flowing out before the actuator has descended completely. When the pressure of 9-10 bar has reached inside the circuit (about 10 sec.), the safety valve opens. This allows cold water to flow into the boiler while the previously warm water flows out and filters through the cartridge. The mixture produced (coffee, tea, chocolate, cappuccino, etc.) flows through a nozzle into the cup.

At the end of the cycle, the second solenoid valve closes and exhausts the remaining hot water under overpressure from the third way into the collecting tank. Then the first solenoid valve closes and water under pressure inside the actuator releases from the third way into the tank. The actuator returns into its rest position under the effect of the spring.

Selecting a different control means only hot water releases. A two-way solenoid valve that connects directly to the boiler, intercepts the hot water and pours it directly into the cup through a different nozzle.

Suitable Solenoid Valves

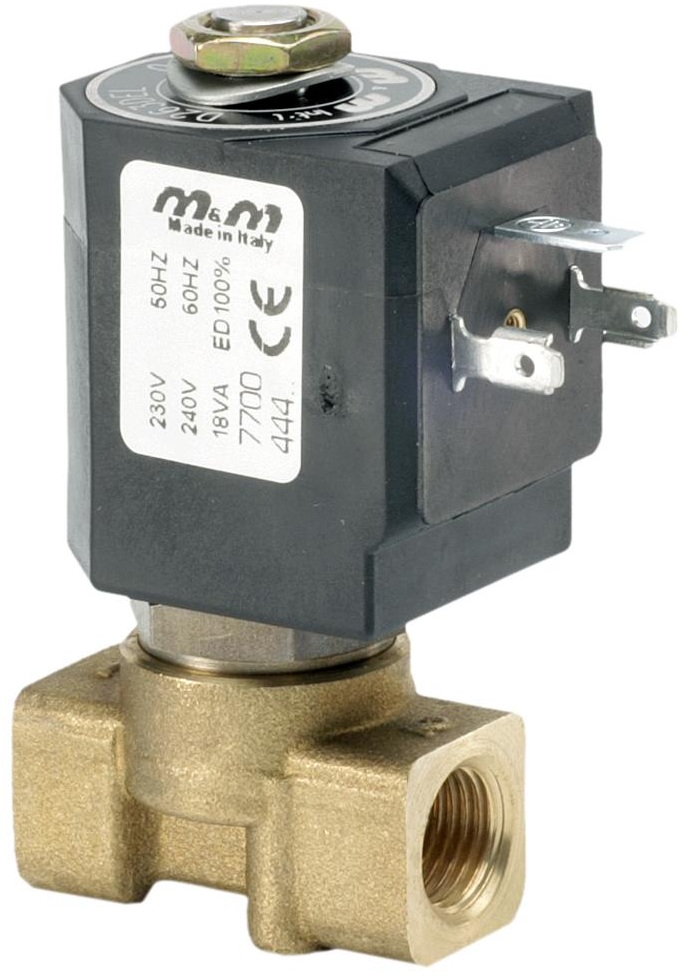

The types B297 and B397 are the most suitable valves on the market for this application. Unlike valves from less experienced competitors, a stainless steel orifice is pressed on a brass body. Whereas bush and tube are made of stainless steel and not machined into the brass body. Price is a key factor but quality connected to a reduced maintenance should be a given emphasis.

The same principal applies when making manifold solenoid valves, which finds the most prominent use in hot drink dispensing machines. Our engineers have vast experience in this field, designing and manufacturing solenoid manifold valve assemblies specific to the manufacturer’s requirements.

If you are a coffee or drinks machine manufacturer looking for a reliable valve supplier with high-quality products please get in contact with V-Flow Solutions solenoid valve department. We will gladly look at your requirements and budget.

Why not drop by our offices to speak with our engineers and sample some of our coffee.

If you would like more information or to get in touch with our technical team, you can contact us by;

Telephone: 01234 855888

Email: sales@v-flowsolutions.co.uk

Alternatively you can use the contact form below.