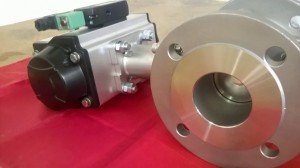

Spring Return Pneumatic Actuator with Namur Solenoid Valve

TWITTER

This spring return pneumatic actuator fitted with a 2 ½” stainless steel ball valve, 100mm extension bonnet and NAMUR solenoid valve was recently assembled and tested in our workshop for a customer who manufactures and supplies animal feed milling equipment and grain drying/handling machinery.

You can view the V-Flow range of Pneumatically Actuated Valves here.

The pneumatic actuator operates at 2.5 to 8 bar pressure and is suitable for valves with a torque of up to 89Nm. It is constructed from extruded aluminium alloy and is hard anodized to protect against corrosion of internal and external surfaces. The working temperature on this model ranges from -20°C up to 80°C.

The actuator has a 90° rotation which can be adjusted ± 5° at each end of the stroke by fine tuning the stop bolts. The open or closed position of the actuator is shown by an indicator on the top of the body. A valve position monitor could also be fitted. This particular model is set to be normally closed – when the air supply is shut off the internal springs return the actuator to the closed position. The option of having the actuator set to normally open is also available.

The ball valve is mounted to a 100mm extension bonnet which is connected to the actuator via the F07/F10 mounting pad. The ball valve is constructed from stainless steel with TFM 1600 seals (modified granular PTFE).

The air supply to the actuator is controlled by a 110v NAMUR solenoid valve fitted to the ports on the side of the body. The actuator will not operate until the solenoid valve is energised allowing the air supply through to the actuator. As this is a spring return pneumatic actuator the solenoid valve is a 3/2 configuration, but this can be easily converted to 5/2 for double acting pneumatic actuators.

After assembly a full function test was carried out before the unit was despatched to our customer.

A NAMUR solenoid valve, also known as a spool valve, mounts directly onto the ports of the pneumatic actuator through a NAMUR interface. It is used to control the action of the actuator.

They are available in 3/2 (for single acting) or 5/2 (for double acting) configurations.

NAMUR solenoid valves are recommended for use in sensitive areas such as clean rooms, pharmaceutical industry processes and food processing sectors.

If you would like to talk to one of our experienced engineers about NAMUR valves or pneumatic actuated packages, contact us on 01234 855888 or email sales@v-flowsolutions.co.uk

Click on the product categories above to view details

We use Cookies to improve your user experience. By continuing on this site you are agreeing to the use of cookies. Find out more